Newsletter

Liam Bates, CEO and Co-founder of Kaiterra, recently presented a webinar about the role of continuous monitoring for achieving certification in the WELL v2, LEED v4, and RESET Air building standards. Watch the full video or read the highlights below.

Watch the video:

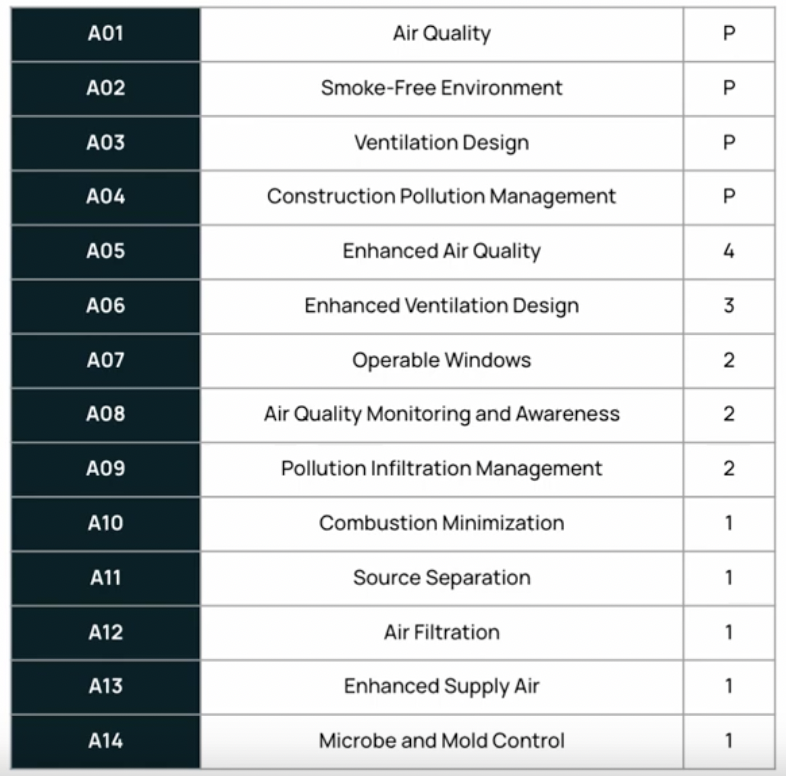

Air Concept in WELL v2

The WELL Air concept is the first module of ten concepts under the WELL Building Certification (WELL v2, Q4 2022) and is key to achieving certification. Features under the Air Concept can be achieved via multiple pathways, including sensor data, performance testing, technical documents, on-site photographs, a letter of assurance from the engineer, and on-going maintenance reports. In this section, we will focus on the features that can be achieved and validated by sensor data or performance tests.

A01: Air Quality Precondition

The first feature in the Air Concept is A01, which sets the minimum air quality standards that must be achieved for specific key pollutants. This feature comprises five parts, including particulate matter, organic gasses, inorganic gasses, radon, and measurement.

PM2.5

Under WELL, there are three options for maintaining acceptable levels of PM2.5 and PM10. Option 1 requires PM2.5 levels to be under 15 micrograms per cubic meter. This can be verified using sensor data or annual performance testing. Option 2 offers a higher threshold where the annual average outdoor PM2.5 level is above 35 micrograms per cubic meter, while option 3 evaluates IAQ by looking at a percentage decrease from outdoor levels.

VOCs

The second part of A01 concerns volatile organic compounds (VOCs). These can be measured and controlled through either periodic performance testing or continuous data from sensors installed within the space.

Inorganic Gasses

Inorganic gasses, such as carbon monoxide and ozone, are covered in the third part of A01. Like VOCs, inorganic gasses can be managed through one-off on-site performance tests or continuous monitoring using appropriate sensors.

Radon

Radon, a naturally occurring radioactive gas, is the focus of part four of A01. To ensure low radon levels, buildings must obtain a letter of assurance from an engineer, or conduct annual radon testing.

Measurement

The fifth part of A01 addresses the need for measuring these parameters at least once per year. Fortunately, if a building has continuous monitoring systems in place, conducting additional on-site visits for measurements may not be necessary.

A03: Ventilation Design

A03, another prerequisite of the WELL Air concept, is focused on ventilation design. This feature aims to ensure that buildings have high standards of ventilation in place. The various options available to comply with A03 are covered below:

Options 1-3

The first three options for achieving A03 are focused on adhering to recognized guidelines such as ASHRAE 62.1, and must be verified by a letter of assurance from an engineer.

Option 4

The fourth option for A03 compliance involves measuring CO2 levels in the building and maintaining them at 900 ppm or less. This approach is particularly suitable for buildings that utilize continuous air quality monitors.

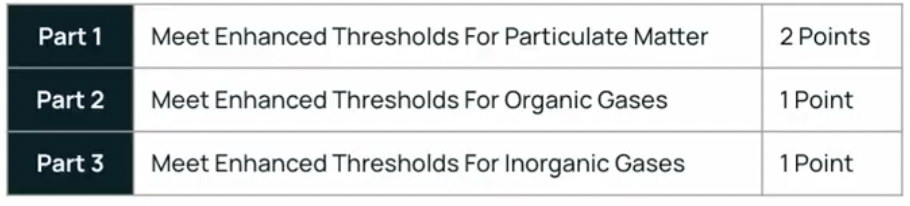

A05: Enhanced Air Quality Optimization

The A05 feature focuses on enhanced air quality optimization, and is far stricter than the minimum requirements. This feature offers extra points for reducing levels of particulate matter, organic gasses, and inorganic gas within a building. A maximum of four points are available for achieving this feature.

While the basic requirement for PM2.5 is 15 micrograms per cubic meter, reducing the PM2.5 levels to 10 micrograms per cubic meter or lower can earn a building two additional points for their WELL certification. Similarly, achieving improvements in organic and inorganic gas concentrations can also contribute to gaining extra points under the A05 feature.

A06: Enhanced Ventilation Design

A06 focuses on the enhanced ventilation design - or going above and beyond the minimum requirements for building ventilation. This feature offers additional points for achieving better ventilation and air quality management. One critical aspect of A06 is reducing CO2 levels using sensor data to demonstrate the effectiveness of the ventilation system.

Option 4: Ventilation Monitoring

Option 4 under A06 involves ventilation monitoring using sensor data. By meeting specific carbon dioxide thresholds in occupiable spaces, a building can earn extra points for its WELL certification. For instance, while the initial CO2 level requirement is set at 900 ppm, lowering it to 750 ppm, as evidenced by sensor data, can contribute to earning two extra points. In total, up to three points are available under A06 for buildings that successfully implement enhanced ventilation design and demonstrate the effectiveness of their air quality management initiatives.

A08: Air Quality Monitoring and Awareness Optimization

A08 in the WELL Air concept is centered around continuous monitoring and promoting air quality awareness through the use of IAQ monitors. This feature offers two additional points for WELL certification and consists of two key components:

Component 1: Installing IAQ Monitors

The first component involves deploying IAQ monitors in the building and continuously collecting IAQ data. Monitors must measure at least three of the key parameters, typically including PM2.5, carbon dioxide (CO2), and total volatile organic compounds (TVOCs).

Component 2: Promoting Air Quality Awareness

The second component of A08 focuses on increasing air quality awareness among building occupants. To achieve this, air quality metrics must be presented on display screens or accessible through web apps or phone applications. By installing an air quality monitor with a display, such as the Sensedge Go, both components of A08 can be addressed simultaneously.

WELL: Air Concept Summary

The Air Concept plays a crucial role in achieving the WELL Building Standard. Meeting the IAQ-related prerequisites is a fundamental requirement for obtaining WELL certification, while a total of 18 points can be earned through the Air Concept.

Many of these points are achieved by testing and verifying air quality, which, until recently, was only possible through performance testing — WELL projects had the option to install continuous monitors but these devices were unable to meet all of the testing requirements in A01, so projects still had to conduct performance testing.

With the launch of the Kaiterra Sensedge Go, however, continuous monitoring can now completely replace performance testing for air. By monitoring all of the parameters required by A01, the Sensedge Go is the first IAQ monitor to not only eliminate the need for performance testing but also satisfy two Air concept preconditions (A01 and A03) and achieve seven optimization points for Air (in features A05, A06, A08).

On top of monitoring all required air quality parameters, the Sensedge Go also measures temperature and relative humidity, allowing WELL projects to meet precondition T01 and score two optimization points in features T06 and T07. Altogether, the Sensedge Go delivers a grand total of three preconditions and nine optimization points in WELL. This can significantly impact a building's certification level, bringing you from silver to gold, or nearly from gold to platinum.

Indoor Environmental Quality in LEED v5

Indoor Environmental Quality (IEQ) is one of the seven core categories in LEED certification.

The U.S. Green Building Council (USGBC) is currently finalizing v5 of LEED, which is expected to officially roll out in early 2025. There have been two rounds of Public Comments for LEED v5 so far, both of which propose significant differences in IAQ requirements from LEED v4.1 — namely, a broader range of air quality parameters to measure, a lower emphasis on occupant surveys, and a greater focus on verifying building design and performance (with continuous monitoring for example).

In this section, we’ll be looking at Public Comment 2 of LEED v5, breaking down requirements by BD+C and ID+C projects and O+M projects. We will update the content below as soon as LEED v5 is finalized this year.

LEED BD+C and ID+C Projects

IAQ also plays a vital role in LEED Building Design and Construction (BD+C) and Interior Design and Construction (ID+C) projects. These projects have specific prerequisites and optional enhancements that can contribute to extra credits. Key aspects include data-driven IAQ performance and enhanced indoor air quality strategies.

Fundamental Air Quality Prerequisite

The Fundamental Air Quality prerequisite ensures that the building provides occupants with an above-average level of IAQ that promotes health and well-being. While this prerequisite does not push for maximum optimization of healthy indoor environments, it sets a standard of minimum requirements. These include:

- Investigating outdoor air quality via ASHRAE 62.1-2022 requirements

- Meeting ASHRAE 62.1-2022 standards for ventilation and filtration design

- Implementing entryway systems to capture dirt and particulate matter at building entrances

Enhanced Air Quality Credit

The Enhanced Air Quality credit offers buildings the opportunity to earn one additional point in LEED by implementing advanced strategies that further protect occupant health and well-being. To earn this credit, a project must choose between one of two options: increasing outdoor air ventilation rates by at least 15%, or enhancing IAQ design to meet lower air quality thresholds.

Continuous IAQ monitoring can help achieve the second strategy by verifying projects meet the following thresholds:

| Design Compound | Enhanced IAQ Design Limit |

| PM2.5 | 10 µg/m3 |

| Formaldehyde | 20 µg/m3 |

| Ozone | 10 ppb |

Air Quality Testing and Monitoring Credit

The Air Quality Testing and Monitoring credit offers additional opportunities to earn two IAQ-related points for LEED certification. The primary goal is to optimize IAQ management and find new opportunities to create a healthier indoor environment. There are two options through which buildings can achieve these points.

Option 1: Pre-Occupancy Air Testing

The first option involves taking baseline IAQ measurements after construction is complete and before occupancy begins. The number of measurements required depends on the total occupied floor area, ranging from one measurement for <5,000 ft2 of space to 10+ measurements for >200,000 ft2 of space.

Projects can choose to measure one or both sets of parameters with one-time testing, and can achieve one to two points by showing they meet the following thresholds:

1. Particulate matter and inorganic gases (1 point):

| Contaminant | Concentration Limit (µg/m3) |

| Carbon monoxide | 9 ppm; no more than 2 ppm above outdoor levels |

| Particulates (for projects in attainment areas) |

ISO class 8 or lower per ISO 14644-1:2015 OR meet PM10: 50 µg/m3 PM2.5: 12 µg/m3 |

| Particulates (for projects in non-attainment areas) |

ISO class 8 or lower per ISO 14644-1:2015 OR meet PM10: 50 µg/m3 PM2.5: 35 µg/m3 |

| Ozone |

0.07 ppm OR 0.01 ppm for projects pursuing Eqc: Enhanced Air Quality Option 1 Path 2 |

2. Volatile organic compounds (1 point):

| Contaminant | Concentration Limit (µg/m³) |

| Formaldehyde 50-00-0 | 20 µg/m³ (16 ppb) |

| Acetaldehyde 75-07-0 | 140 µg/m³ |

| Benzene 71-43-2 | 3 µg/m³ |

| Hexane (n-) 110-54-3 | 7000 µg/m³ |

| Naphthalene 91-20-3 | 9 µg/m³ |

| Phenol 108-95-2 | 200 µg/m³ |

| Styrene 100-42-5 | 900 µg/m³ |

| Tetrachloroethylene 127-18-4 | 35 µg/m³ |

| Toluene 108-88-3 | 300 µg/m³ |

| Vinyl acetate 108-05-4 | 200 µg/m³ |

| Dichlorobenzene (1,4-) 106-46-7 | 800 µg/m³ |

| Xylenes-total 108-38-3, 95-47-6, and 106-42-3 | 700 µg/m³ |

Option 2: Continuous Indoor Air Monitoring

Air quality monitoring is the second option and is a more reliable method, since it evaluates air quality continuously and can surface issues that may not be found through one-time air testing. This option awards one point towards LEED certification. Indoor air monitors must measure each of the following parameters continuously:

- CO2

- PM2.5

- TVOC

- Temperature

- Relative humidity

Installing monitors alone will award one point, but projects will have to also test their air (for either particulate matter and inorganic gases or volatile organic compounds) to get the maximum two points for this credit.

LEED O+M Projects

For LEED Operations and Maintenance (O+M) projects, IAQ is also a major component of the Indoor Environmental Quality category. This category includes one prerequisite and three credits for maintaining and optimizing IAQ, with a key emphasis on ventilation and filtration. In total, LEED O+M projects can earn up to 16 points by optimizing their IAQ strategies.

Verification of Ventilation and Filtration Prerequisite

The Verification of Ventilation and Filtration prerequisite seeks to establish a building’s ventilation procedures and understand how ventilation performance impacts overall IAQ. Projects must provide information about their ventilation system’s operation and preventative maintenance measures, in addition to investigating outdoor air quality to identify potential contaminants that could enter the building.

Mechanically ventilated spaces are also required to:

- Calculate the minimum amount of outdoor air for their building required by ASHRAE 62.1-2022

- Measure the amount of outdoor air that each ventilation system brings in

- Compare these two numbers to determine if their space is properly ventilated or needs maintenance

- Identify the level of filtration that each ventilation and HVAC system provides to occupied spaces (MERV 13 filters are encouraged but not required)

Air Filtration Credit

The Air Filtration credit offers one point for projects that demonstrate that their filtration procedures exceed basic standards. Every ventilation system that delivers outdoor or recirculated air to occupied spaces has to either be MERV 13 (or higher) or have an equivalent filtration media class of ePM1 50% (or higher).

Ventilation Performance Credit

Similar to the Air Filtration credit, the Ventilation Performance credit awards additional points for projects that have outdoor air ventilation rates that meet or exceed ASHRAE 62.1-2022 (note: these increased ventilation rates should supply 95% of regularly occupied spaces). This credit provides:

- 3 points for ventilation rates that meet the standard

- 4 points for ventilation rates that exceed the standard by 15%

- 5 points for ventilation rates that exceed the standard by 30%

Indoor Air Quality Performance Credit

The Indoor Air Quality Performance credit offers the highest number of possible points to LEED projects for IAQ optimization. Projects can earn ten points for raising awareness about air quality and seeking out opportunities to further improve their IAQ.

There are three ways to achieve these points; however, projects should note that the first option (continuous monitoring) can earn all ten points (compared to the one-time testing options, which can earn a maximum of five points). All three methods can be used in the same project, but continuous IAQ monitoring will provide a more accurate and reliable data source for IAQ.

Option 1: Continuous Indoor Air Monitoring

To start, projects should install building-grade monitors that measure CO2, PM2.5, and TVOC at intervals no longer than one hour. While installing monitors alone can earn six points, projects can achieve the maximum ten points by demonstrating compliance with these benchmarks:

| Parameter | Benchmark | Points |

| Carbon dioxide (CO2) | > 1000 ppm | 2 |

| 1000 ppm | 3 | |

| 800 ppm | 4 | |

| PM2.5 | > 15 µg/m3 | 2 |

| 15 µg/m3 | 3 | |

| 12 µg/m3 | 4 | |

| TVOC | Any level | 2 |

Option 2: Targeted One-Time Air Testing

The other method projects can use to measure air quality performance is one-time spot checks. For this option, projects should test these parameters at least once per year, along with a comparison of IAQ measurements against outdoor levels:

| Contaminant | Concentration Limit (µg/m3) |

| Carbon monoxide | 9 ppm; no more than 2 ppm above outdoor levels |

| Particulates (for projects in attainment areas) |

ISO class 8 or lower per ISO 14644-1:2015 OR meet PM10: 50 µg/m3 PM2.5: 12 µg/m3 |

| Particulates (for projects in non-attainment areas) |

ISO class 8 or lower per ISO 14644-1:2015 OR meet PM10: 50 µg/m3 PM2.5: 35 µg/m3 |

| Ozone |

0.07 ppm OR 0.01 ppm for projects pursuing Eqc: Enhanced Air Quality Option 1 Path 2 |

| Nitrogen dioxide (NO2) |

40 µg/m3 (21 ppb) |

| TVOC |

N/A (This parameter requires a monitoring device; projects may not earn points for both one-time air testing and continuous monitoring for the same parameter) |

Option 3: Targeted One-Time VOC Testing

Similar to Option 2, this option uses one-time testing and analysis in an accredited lab, but specifically for TVOC. Projects can earn two points by demonstrating that no contaminant exceeds these limits:

|

Contaminant |

Concentration Limit (µg/m3) |

|

TVOC |

N/A (Calculate per EN 16516:2017, CDPH Standard Method v1.2 2017 section 3.9.4, or alternative method with full description included) |

|

Formaldehyde 50-00-0 |

20 µg/m3 (16 ppb) |

|

Acetaldehyde 75-07-0 |

140 µg/m3 |

|

Benzene 71-43-2 |

3 µg/m3 |

|

Hexane (n-) 110-54-3 |

7000 µg/m3 |

|

Naphthalene 91-20-3 |

9 µg/m3 |

|

Phenol 108-95-2 |

200 µg/m3 |

|

Styrene 100-42-5 |

900 µg/m3 |

|

Tetrachloroethylene 127-18-4 |

35 µg/m3 |

|

Toluene 108-88-3 |

300 µg/m3 |

|

Vinyl acetate 108-05-4 |

200 µg/m3 |

|

Dichlorobenzene (1,4-) 106-46-7 |

800 µg/m3 |

|

Xylenes-total 108-38-3, 95-47-6, and 106-42-3 |

700 µg/m3 |

RESET Certification: Air Module

RESET is a modular green building standard that prioritizes occupant health within the built environment. RESET is set apart by its performance-driven approach, primarily relying on sensor readings and measurements as the foundation of the standard. Unlike WELL and LEED, which allow for on-site testing, RESET requires real-time, continuous sensor readings for certification.

RESET has several modules, including materials, air, water, energy, and circularity. In this discussion, we will focus on the RESET Air module, which emphasizes IAQ and its impact on health and well-being. The module applies to both commercial interiors and core and shell building types.

RESET Air Requirements

RESET certification emphasizes the importance of continuously monitoring air quality, as it changes over time due to occupancy, user behavior, and seasonal variations. RESET Air requires constant measurement of five key parameters: particulate matter (PM2.5), total volatile organic compounds (TVOC), carbon dioxide (CO2), temperature, and relative humidity.

RESET Air - Commercial Interiors

For commercial interiors, there are two performance levels that can be achieved: acceptable and high-performance. The acceptable level thresholds for PM2.5, TVOC, and CO2 are under 35 micrograms per cubic meter, 500 micrograms per cubic meter, and 1000 ppm, respectively. While there are no specific requirements for temperature and humidity levels, these parameters must be measured.

The high-performance thresholds are significantly stricter, especially for PM2.5 and CO2. High-performance PM2.5 levels must be under 12 micrograms per cubic meter, and CO2 levels must be no more than 600 ppm.

Data-Driven IAQ: Achieving IAQ Requirements

The first step to enhancing IAQ is monitoring. Traditional methods involve having a third-party consultant or a professional inspect the building, recording measurements at different locations. However this method has several drawbacks, including the limitation of only providing one-time measurements and potential inconsistencies in location and timing.

For WELL certification specifically, third-party performance testing used to be the only way to meet air quality testing requirements, because no IAQ monitors measured all the parameters needed to satisfy precondition A01.

Now, monitors like the Sensedge Go make it possible for WELL projects to only use continuous IAQ monitors because they measure all parameters required by A01 — and, on top of replacing performance testing, the Sensedge Go can help projects earn up to nine optimization points for their certification with one solution.

Compared to one-time testing, continuous monitoring offers a more advanced and effective approach to improving IAQ. Installing sensor technology in various parts of the building allows for real-time data collection and analysis, providing a comprehensive picture of the air quality and identifying trends or patterns.

With continuous monitoring in place, you can:

- Identify and address issues promptly: Detect changes in IAQ in real-time, enabling prompt action to correct any problems before they become severe.

- Establish informed strategies: Gain a better understanding of how various factors (e.g., occupancy, time of day, season) affect IAQ, allowing for targeted strategies to address specific issues.

- Evaluate the effectiveness of interventions: Implementing continuous monitoring means you can track the impact of any interventions or improvements made to the building's IAQ, ensuring they are effective and identifying any further adjustments needed.

- Communicate and engage with occupants: With comprehensive data, you can effectively communicate the efforts made to improve IAQ with building occupants, increasing their awareness and comfort level.

In conclusion, transitioning from traditional snapshot measurements to continuous monitoring is essential for effectively managing and improving IAQ. Leveraging advanced sensor technology and real-time data allows stakeholders to identify trends, address issues promptly, and make informed decisions to optimize their indoor environment. This data-driven approach ensures the well-being of building occupants and contributes to compliance with green building certification standards like WELL, LEED, and RESET.

Energy Savings and IAQ Management

One common mistake that building managers make when trying to improve IAQ is adopting excessive ventilation practices, such as constantly pumping large volumes of fresh air into the building. A holistic air quality monitoring system can help strike the right balance between ventilation and energy efficiency.

Ventilation accounts for a huge portion of a building's energy consumption. Heating, Ventilation, and Air Conditioning (HVAC) systems are responsible for approximately 40% of a building's energy use, while buildings expend around 40% of global energy. Therefore, it is crucial to optimize ventilation in buildings to both maintain healthy indoor environments and minimize energy use.

Building managers can adjust ventilation levels based on real-time data by implementing continuous IAQ monitoring systems. For instance, if the CO2 levels in the building are already well within the acceptable range, the HVAC system can be slowed down, reducing the amount of fresh air being pumped into the space. This approach leads to energy savings and cost reductions without compromising occupant health and satisfaction.

Not Just About the Standards

In short, IAQ strategies are essential for achieving LEED, WELL, and RESET certification. Continuous monitoring can earn you a huge amount of points for both WELL v2 and LEED v4, and is perhaps the most important part of the RESET Air standard. Not only this, but continuous monitoring allows you to identify IAQ related issues quickly, establish informed strategies, evaluate the effectiveness of your interventions, and make large savings on your energy bills.

Kaiterra’s commercial air quality monitoring solutions are great options for not only WELL, but also RESET, LEED, and more. Find out more about our commercial line of air quality monitors by reaching out to our team below!

.png?width=200&height=148&name=Menu%20C%20(2).png)

.png?width=307&height=228&name=Menu%20-%20D%20(1).png)

.png)