Newsletter

Commercial Air Quality Monitors 101 — Modules & Calibration

Imagine this: You’re working on an important document for your boss, and you’ve just finished the last paragraph. You go to print a copy that you will submit just in time, but suddenly realize the printer is out of ink.

So you take the printer, unplug all the cables, remove the paper from the inside, pull the original packaging out from your storage room, and pack it up carefully in the original box. You then call a shipping company to come to pick up your printer and have them ship it back to the manufacturer.

Unfortunately, the manufacturer is based in China, and it will take three weeks to get there.

When the printer arrives in China, it is filled with ink again, and then shipped back to you. On the way back, the printer gets stuck at customs, and you end up paying import duty for something you had already imported once before. The printer arrives back in your office 6 weeks after you had first run out of ink. Congratulations, now you can finally print your document!

Does this seem strange?

Well, this is the state of air quality monitors today — at least it was until we created the Sensedge. And the more recently introduced, Sensedge Mini.

Air quality monitors need to be re-calibrated at regular intervals (many manufacturers suggest once a year). Over time, air quality sensors degrade or become dirty, in which case the air quality monitor needs to be sent back to the manufacturer so the sensors can be cleaned and re-calibrated or replaced entirely.

For example, monitors or particle counters that measure particulate matter (PM2.5) are typically optical sensors. They measure particles by shining a laser beam above a sensor that picks up on incredibly subtle changes in light, much like a digital camera’s sensor.

By operating a sensor over an extended period of time, high levels of dust can start to collect inside. Airflow can be affected by the dust collecting on the fans or inside the pumps, and dust will slowly build up on the optics of a device. Imagine leaving a camera in a dusty room for a year and then using it to take a photograph. While you may be able to use it, the quality of the image will be highly affected, and you won’t get the same clear, crisp or accurate photo you would have with a brand new camera.

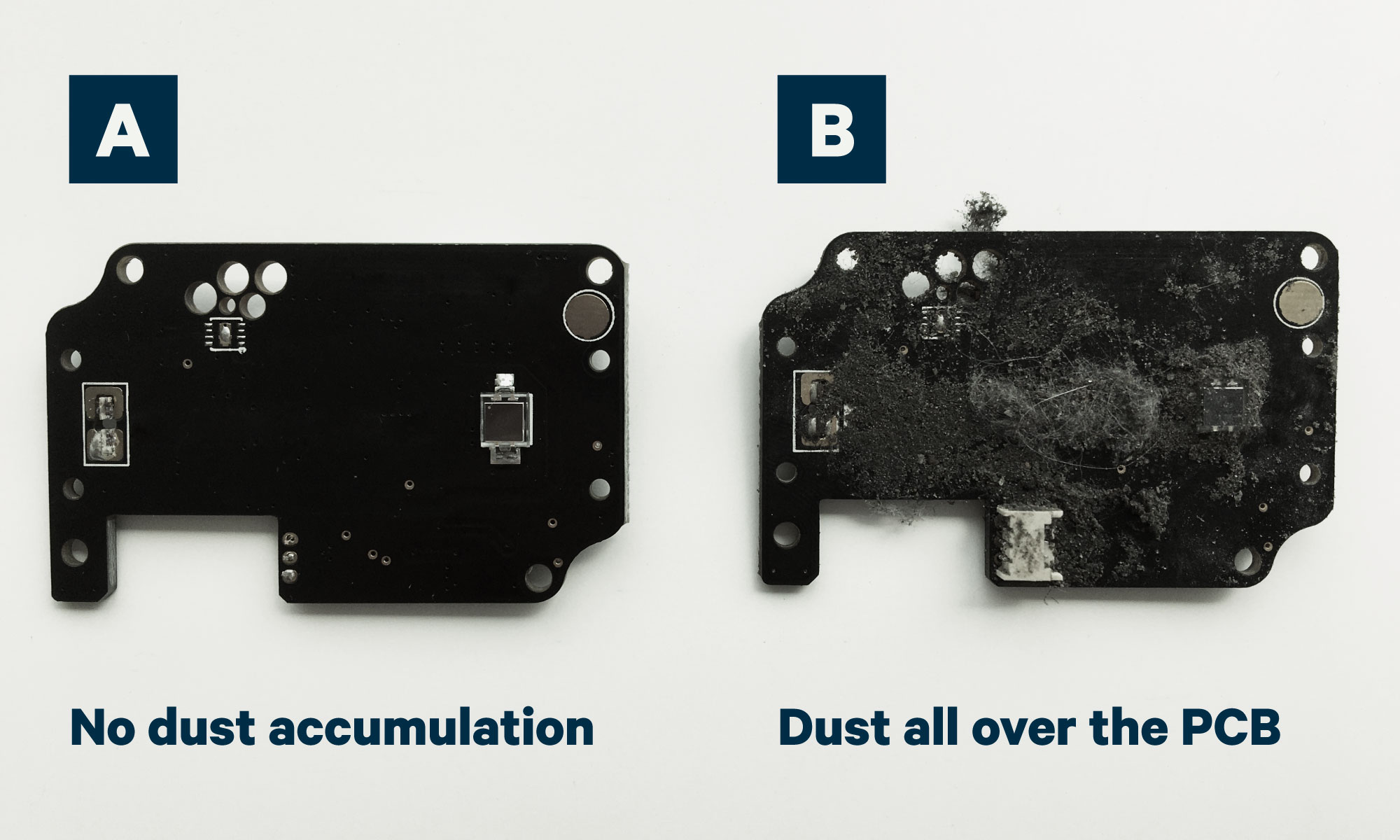

Dust accumulation over an old PCB (B) compared to a new one (A). The optical sensor is on the right side of the board.

With an optical sensor, there is simply no way around cleaning or re-calibrating the device. Some companies claim to offer “software calibration”, but this is more like taking a photo with a dusty old camera, and then trying to sharpen the image in Photoshop. While it might look a little better, you still haven’t fixed the problem of the dirty lens.

Calibration Requirements

This is why most building certification standards, including WELL and RESET, require mandatory sensor calibrations.

If you care about the accuracy of your air quality monitor, or about either of the certifications listed above, you need to re-calibrate your air quality monitor.

Returning to our printer analogy, imagine dealing with all 30 (or 300!) printers in your building suddenly running out of ink at the same time. Other than the logistical nightmare, there are no longer any printers in the building! Re-calibrating all your air quality monitors at the same time can be just as bad, particularly if these are tied to the building’s HVAC system.

Solution: A Modular Sensor System

Thankfully, we spent countless hours developing a modular sensor system for the Sensedge and Sensedge Mini, so that re-calibrating a sensor is just as easy (in fact, I think it’s even easier) than replacing a printer cartridge. The devices don't even need to be opened, simply slide the old modules out, and insert new ones. The entire process takes only 15 seconds, and at the end, a brand new set of sensors will be sitting inside your Sensedge, or Sensedge Mini, completely free of dust.

Of course, the Sensedge’s modular design also means that if you want to measure a different pollutant, or set of pollutants, you can simply swap out the module for a new one that does exactly what you want.

Would you consider using a printer that requires being sent to the manufacturer every time it ran out of ink? Unless you’re willing to do the same for your monitors, take a good look at our products, Sensedge and Sensedge Mini, with easy-to-replace modules.

You can also watch the short & sweet demo of our newest, RESET-certified air quality monitor Sensedge Mini to see how you can start optimizing the air quality in your building today.

.png?width=200&height=148&name=Menu%20C%20(2).png)

.png?width=307&height=228&name=Menu%20-%20D%20(1).png)

.png)