Newsletter

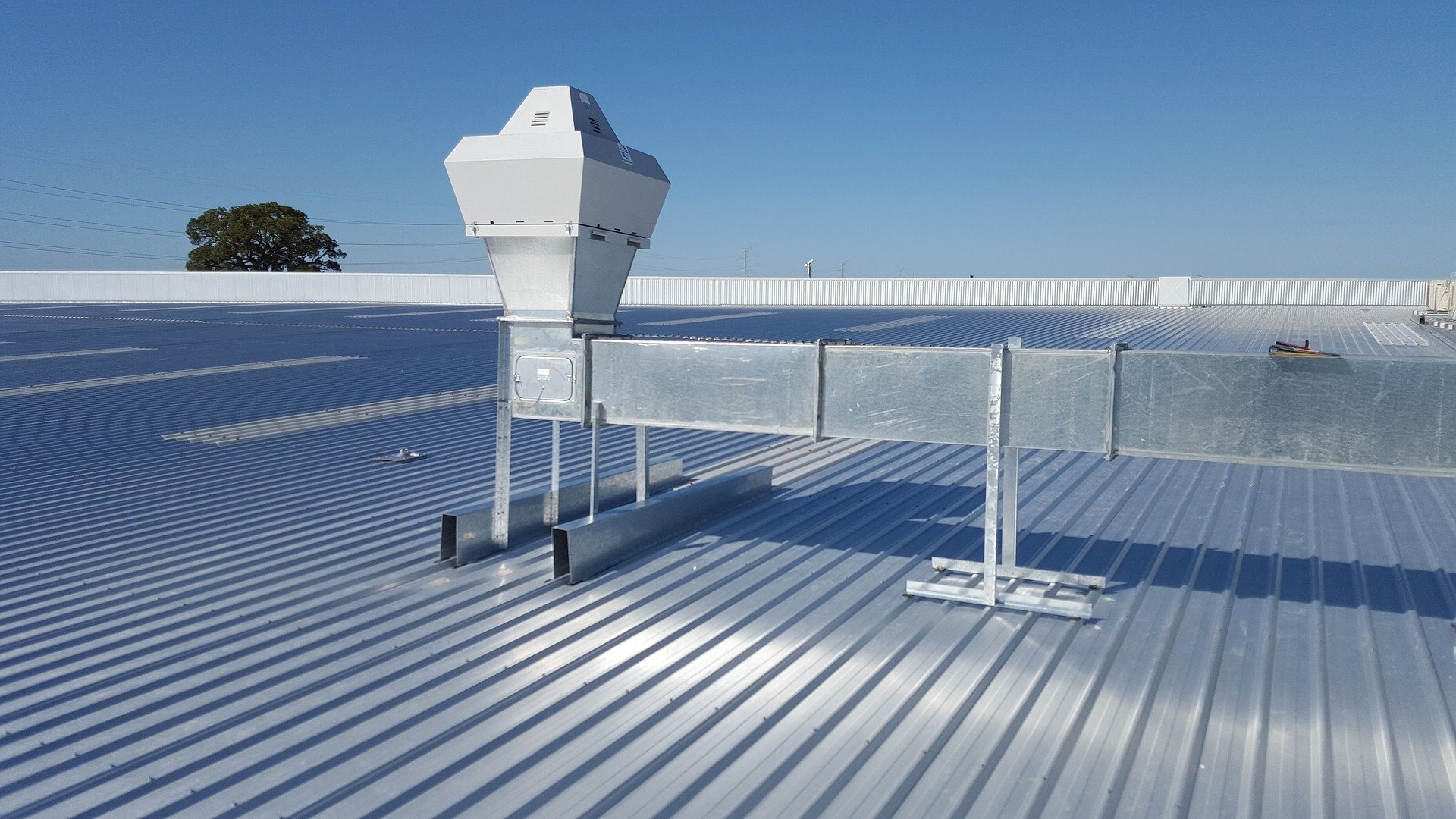

Where clean air is needed, an air filter can be spotted right away. Used in HVAC systems to capture and prevent particles from entering the conditioned air stream, air filters bring in a multitude of benefits to a building and its occupants, including reduced exposure to air contaminants and larger particles kept out of your HVAC system to prevent damage.

Unfortunately, like any man-made thing, air filters eventually lose their effectiveness. Over the course of its life, a filter will become loaded with particles and clog up due to dirt, debris, and dust accumulation. Consequently, clogged filters can lead to an undersupply of air, substantial loss of energy efficiency, noisy fan operations, reduced filter performance, and, eventually, result in damage to the filter itself.

Companies who invest in air filtration units are rarely filter experts themselves — but with the consequences of this knowledge gap being so high, wouldn't it be great if your air filter could alert you when it became clogged and lost its efficiency?

Air filtration monitoring exists for this very reason. Made possible with the latest sensor technologies, air filtration monitoring can bring cleaner air, lower electric bills, and help operate your HVAC system more efficiently.

Do You Change Your Filters Too Late?

For the most part, filters are still changed according to fixed replacement schedules, as a result of visual inspections by service technicians or based on rudimentary differential pressure switches. The reality is that, in most instances, filters are changed too late, resulting in reduced safety, energy efficiency and performance of the application in question.

In the last few years, an increasing shift from preventive to condition-based maintenance (CBM) has taken place in the manufacturing industry. Sensors observe the state of different parts and maintenance is only performed when certain indicators show signs of decreasing performance or upcoming failure.

Sensor Technologies for Air Filter Monitoring

Today’s emerging sensor technologies act as a “filter change” reminder, helping monitor key HVAC system performance indicators and ensuring that the air filters are serviced at the optimal time. While various options exist, today we will explore three of the most commonly measured HVAC performance metrics:

Filter monitoring through measuring air pressure drop (Differential Pressure Sensors)

Contaminated air filters increase the pressure loss in ventilation channels and systems, which requires more fan power and increases energy costs. Electronic filter monitoring with an integrated differential pressure sensor measures the pressure drop over the filter and promptly triggers a message to replace the filter. Sensitive pressure sensors therefore play an important role in the economical operation of HVAC systems.

Filter monitoring through measuring airflow (Airflow Sensors)

Monitoring flow through the filter can also be an indicator of filter health. As the filter reaches the end of its useful life, the flow rate will diminish and, when the filter is totally clogged, cease completely. When placed in front of a vent, airflow sensors measure the rate at which air is being pushed out of your HVAC unit. A decrease in this rate, for example, indicates that your filters need to be replaced and calls for immediate attention.

Filter monitoring through measuring particulate matter concentration (Particulate Matter Sensors)

Air quality monitoring can inform you about the status of your HVAC air filter, much like taking a pulse. When integrated into a variety of systems, the particulate matter (PM) sensors can help alert occupants to the presence of airborne particulates and trigger supporting equipment to improve indoor air quality. Should one floor — or a specific section in the building— have significantly worse air quality than the others, you'll know that the HVAC system needs repairs.

Kaiterra’s Sensedge and Sensedge Mini air quality monitors provide reliable readings of particulate matter levels — along with numerous other indoor pollutants parameters — and can be easily retrofitted to existing HVAC systems.

Optimizing Air Filter Performance the Smart Way

Precise filter monitoring adds value to many applications in HVAC. While pressure and airflow sensors help determine the correct moment for a filter change, particulate matter sensors can pinpoint problematic areas for increased response accuracy. Combined together, filter monitoring can protect occupants and equipment by ensuring clean air and leads to lowered HVAC costs and more energy-efficient and sustainable operation.

The capabilities of particulate matter sensors extend beyond identifying problematic areas. When used as part of a complete indoor air quality monitoring system, PM sensors can help optimize the use of HVAC systems to maintain air quality in a smart way, differentiating when and where action is really needed.

Buildings equipped with air quality monitors can leverage indoor readings and compare them against real-time outdoor air quality data to determine when it’s necessary to run outdoor air through the filtration system, and when it’s safe to bring it in directly without any need for filtration. In return, HVAC systems that are used as and when they're required — as opposed to running 24/7— can lead to considerable energy savings and prolong the lifespan of your filters.

The most accurate filter monitoring can be achieved when both the pressure drop and the flow are measured in order to determine the changing pressure across the filter in relation to the air flow. Incorporating strategies like particulate matter monitoring can also provide additional insights and paint a more complete picture of your HVAC system’s overall health.

To learn more about the particulate matter sensors used in our products, download the tech specifications below!

.png?width=200&height=148&name=Menu%20C%20(2).png)

.png?width=307&height=228&name=Menu%20-%20D%20(1).png)

.png)