Newsletter

It’s 2021, and the importance of indoor air quality monitoring is clearer than ever. If you’ve decided it’s time to gain visibility into the state of air quality in your buildings, the first thing you’ll need to think about is how you manage air quality monitoring and testing. In this article, we’ll review two popular approaches: spot testing and continuous monitoring, explain the differences between them, and offer some pointers on how to decide on the preferable strategy for your organization.

What is Air Quality Spot Testing?

In spot testing, the indoor space is sampled periodically, ranging anywhere from a few hours to a few days, for common air pollutants such as VOCs and particulate matter. The building manager or facility manager typically doesn’t own the air quality monitors and instead relies on an external team to come on-site on one or more occasions, collect and analyze samples, and send a detailed report after the fact.

Limitations of Spot Testing

Spot testing was the more common approach to indoor air quality monitoring in the past, since purchasing air quality monitors used to be prohibitively expensive and the devices were difficult to maintain. However, this approach suffers from multiple disadvantages due to the very limited scope of measurement that it permits:

Gameable

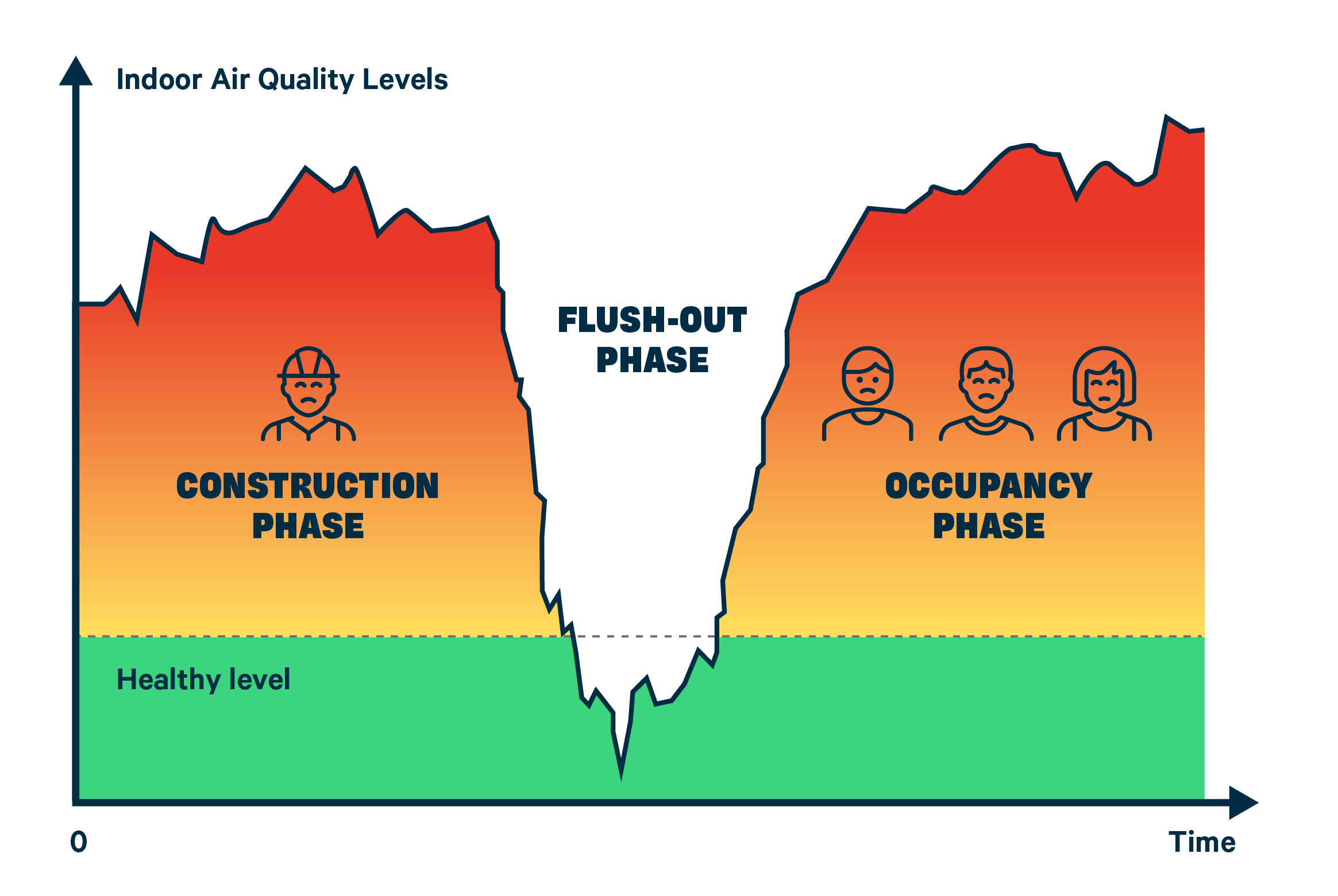

The results of a spot test often depend on the time in which the sample is collected, which makes them easy to game and hurts their reliability. For example, an organization might schedule a test during low-occupancy periods, such as during a building’s flush-out phase (see illustration below). This can result in building occupants living or working in unhealthy conditions that go unnoticed, which leads to myriad costs in lost productivity, absenteeism and employee dissatisfaction.

Snapshot data makes it difficult to see trends

Unlike in continuous monitoring approaches, which will be covered further in this article, a spot test ends with a report detailing the air quality situation during the period when samples were collected. When samples are collected only a handful of times each year, it’s difficult to gain a reliable understanding of trends (as there is only a very small number of data points to extrapolate from).Usually not actionable in real-time (or at all)

Since data isn’t collected or analyzed on a day-to-day basis, it’s much harder to catch problems when they’re small. With spot testing, the best case scenario would be that you notice an air quality problem or an issue with HVAC systems at a fairly late stage; and the more likely scenario is that you would fail to notice the problem at all due to the very limited amount of data that’s being collected.High ongoing costs with low ROI

Despite low upfront costs, many buildings, especially those that are applying for green and healthy building certifications, need to have their air quality tested at least annually. These costs accumulate over time. In addition, testing companies generate static reports that pertain only to the specific moment in time when data was collected, making them less actionable - for example, data from spot sampling cannot be used to inform building automation systems. The data is simply less useful than alternative approaches -and reliance on spot testing is thus less cost-effective in the long term.Continuous Monitoring: The Modern Approach to Indoor Air Quality

In continuous monitoring, an organization uses indoor air quality monitors that are installed throughout the building in order to collect data on an ongoing basis, and gain real-time visibility into the current state of air quality in an office or other indoor space. Unlike spot tests which are only conducted a handful of times each year, this type of monitoring happens consistently in the background, allowing building managers and facility managers to track the data and find anomalies or optimization opportunities.

Example of a real-time air quality dashboard

Advantages of Continuous Monitoring

In recent years, as more simple and affordable commercial air monitors have been introduced (by Kaiterra and other companies), the balance has shifted towards continuous monitoring. With affordability no longer as much of an issue, companies are choosing this approach as it presents numerous advantages over the alternative:

Accurate and actionable data in real-time

With continuous monitoring, organizations can be aware of the state of air quality in their building at any given moment, and respond to changes as they occur, rather than wait for samples to be collected and analyzed or rely on one single data point that’s taken in the past to define your indoor air quality optimization strategy. Changes in air quality are addressed more rapidly and effectively, which has a positive impact on occupant well-being and productivity.More comprehensive representation of your indoor space

Spot testing is typically conducted in a limited area, and within the occupancy rates in the building on the day the samples are collected. This results in a limited scope of insights that can be gleaned from the data, especially in larger indoor spaces, as it is only relevant for the specific spaces that were sampled and the specific occupancy at the time of sampling. Continuous monitoring allows you to place monitors across multiple locations and examine data throughout different periods and times of day, providing a significantly more accurate representation of the state of air quality in your buildings.Ability to see long-term trends

Since data is collected on an ongoing basis and can be stored indefinitely, organizations are able to analyze changes in air quality parameters (such as TVOC) over time and see long-term trends as well as temporary peaks in the data. These trends are almost impossible to identify with spot sampling, which produces only a handful of data points.Higher ROI

While air quality monitors require an upfront investment, organizations typically see returns within a moderate timeframe by eliminating the cost of repeated testing, working with higher-quality data, and gaining certifications. Additionally, in a continuous air monitoring system, ownership over data and the ability to act based on fresh data present opportunities to reduce operational costs and ultimately improve profitability. For example, building managers can notice degradation in some parameters as an indication to run maintenance on HVAC systems before a more serious breakdown occurs or identify opportunities to reduce over-ventilation to save energy costs.Summary: Comparing Continuous Monitoring to Spot Testing

| Continuous Monitoring | Spot Testing | |

| Upfront costs | Medium | Low |

| Ongoing costs | Low | High |

| Period measured | Long-term | Snapshot |

| Ability to see trends over time | Yes | No |

| Reliability | High | Low (due to the ability to ‘game’ the system) |

| Data sharing | Dashboards | Static reports |

| Actionable in real-time | Yes | No |

| Lab analysis of samples | Not available by default | Possible |

When to Combine Ad-Hoc Spot Sampling With Continuous Monitoring

We’ve seen that continuous monitoring offers several advantages in terms of the freshness, reliability, and comprehensiveness of the data you can collect, as well as in the possibilities to take action based on the data or to incorporate air quality parameters in building automation systems. However, there could be instances where you want to combine some level of spot testing in addition to your continuous monitoring systems.

As we’ve covered in our previous article on types of air quality monitors, commercial air monitors are typically built to measure the most common air quality issues and to meet the standards needed for certification programs. However, they might be unable to find trace amounts of very specific chemicals that require lab-grade equipment to measure - this could mean a bulkier, specially-maintained device or a specialized lab testing environment.

Spot tests should be utilized in these (uncommon) scenarios in which you need to conduct ad-hoc tests for a very specific chemical, or run a more thorough inspection for regulatory purposes you should utilize specialized sampling and testing while relying on your own indoor air quality monitoring for regular operations.

How to Reap the Most Benefits from a Continuous Air Monitoring System

We’ve seen there can be multiple benefits to continuous monitoring. However, to gain the most value out of any IAQ monitoring technology you decide to evaluate or purchase, it’s important to keep a few things top of mind:

What should you monitor?

For ongoing monitoring purposes, there are a few parameters that typically have the largest impact on occupant well-being, productivity, and the ability to meet certification standards. These include particulate matter, total volatile organic compounds (TVOC), carbon dioxide, and thermal comfort. You should ensure you have the ability to keep track of all of these parameters in a precise and reliable way.

Choosing the right monitor

Recalibration

Modern air quality monitoring solutions such as Kaiterra’s Sensedge and Sensedge Mini are built in a modular fashion so that you only need to replace sensor modules as a way for recalibration, which eliminates the friction and disruption involved in sending devices back to the manufacturer for recalibration.Measuring parameters

For ongoing monitoring purposes, there are a few parameters that typically have the largest impact on occupant well-being, productivity, and the ability to meet certification standards. These include particulate matter, total volatile organic compounds ( TVOC), carbon dioxide, and thermal comfort. You should ensure you have the ability to keep track of all of these parameters in a precise and reliable way.Data capabilities

How often are measurements taken? Where is data stored, and for how long? How easy is it to gain insights from the data using a visual dashboard, versus analyzing the raw readings?Building certifications requirements

Common certification schemes such as WELL, RESET, and Fitwel require certain standards when it comes to ongoing air quality monitoring, so it’s worth ensuring that any device you consider can meet these standards.To learn more about this topic, check out our previous article on evaluating and choosing commercial air monitors.

Closing: Finding a Winning Air Quality Strategy for Your Organization

Indoor air quality is an essential component of a healthy building, and monitoring it should be a priority if you’re looking to increase occupant satisfaction and reduce operational costs. In this article, we’ve covered the two most common ways building managers monitor air quality - continuous testing and periodic spot sampling, and compared the pros and cons of each approach.

While every organization is different, most companies see value in continuous indoor air quality monitoring. Real-time monitoring can replace most or all of the spot testing that would otherwise be needed, while the ability to act on data in real time can generate returns that far exceed the upfront cost of implementing commercial air quality monitors.

If you’d like to learn more about how Fortune 500 companies solve their air quality challenges, schedule a free, no-strings-attached consultation with one of our experts:

.png?width=200&height=148&name=Menu%20C%20(2).png)

.png)